Features :

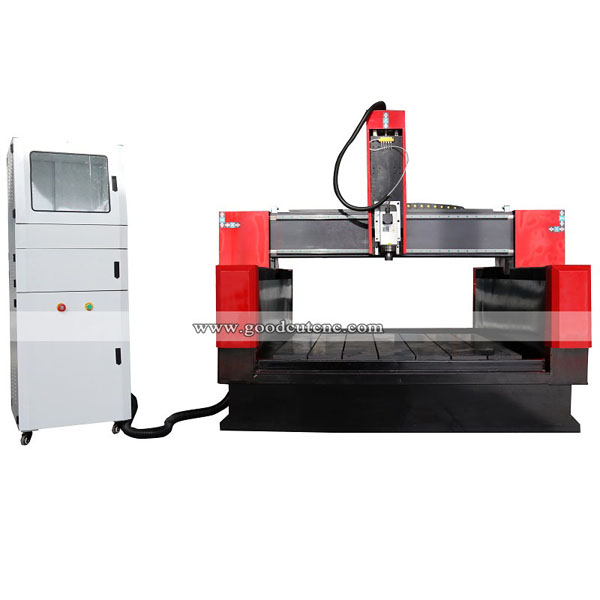

1. Working area:1300*2500/1500*1500mm

2. 5.5kw water cooling spindle

3. Mach3 control system with USB port

4. XY axis gear transmission, Z axis Taiwan TBI ball screw transmission

5. T-slot table with water tank

6. Assistant wheels for loading

7. Heavy duty steel structure frame

8. Taiwan TBI ballscrew transmission

9. Leadshine M860 driver

10. Manual oil lubrication

11.Taiwan HIWIN 25mm square rails guides

12. Fuling inverter

13. Tool box

Optional:

1 Rotary device model professional for cylinder stone colomn

2. Oil spray cooling system for metal

3. Dual-heads or more heads

4. Servo motors (Taiwan brand or Japanese brand)

5. Other custom features

Parameters:

1 | Working area | 1300*2500/1500*1500mm |

2 | Spindle | 5.5KW water cooling spindle |

3 | Spindle speed | 0-24000rpm/min |

4 | Guide rail | Taiwan HIWIN 20mm square rail |

5 | Driving method | X,Y axis by helical gear rack,Z axis by TBI ball screw |

6 | Motors and drivers | Stepper motor450B,Leadshine drivers MA860H |

7 | Control system | DSP controller |

8 | Inverter | Fuling inverter |

9 | Max.idling speed | 25m/min |

10 | Max.working speed | 12m/min |

11 | Machine structure | 8mm thickness welded steel tube, cast iron vertical shafts and steel gantry |

12 | Working voltage | 220-380V/50HZ |

13 | Control cabinet | Independent |

14 | Rotary device | yes, can be option |

Parts images

HQD or Italy HSD spindle, water cooling spindle

Professional big power 5.5kw water cooling spindle, with constant power, has better performance and longer lifespan than normal spindle

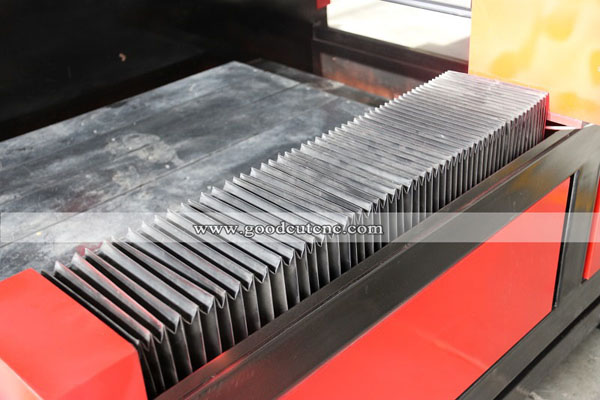

Dust-proof and waterproof design protects the transmission components.

All surroundings of stone cnc router is with stainless steel cover to avoid machine be dusted after long time operation, also All axis use dust proof cover to protect guide rail from water

Transmission: Taiwan HIWIN 20mm square rail and helical rack

Applications :

Stone Industry: Stone, ink-stone cutting, tomb stone, jade and marble products.

Kitchen Ware Industry: Man-made marble cabinet table surface.

Artwork Decoration Industry: Wood crafts, gift box, jewelry box and other exquisite art crafts.

Woodworking industry: Chair, door, window, bed, cabinet, kitchen ware and other furniture; Redwood classical and antique furniture, Exquisite European furniture, decorative products sculpture.

Mold Industry: Engraving copper, aluminum, and other metal molds;Building models, shoes, badge, embossed mould, biscuit, candy, chocolate mould; Artificial marble, plastic sheeting, PVC, wood, foam and other non-metallic mold.

Advertising Industry: Billboard, signage, badges, logo, company plate, signs, emblem, badge, display panels, fair signs, building numbers, signs of decoration, literal hole cutting etc.; 3D character cutting, acrylic cutting, LED/neon channel, lightbox;

How To Use?

Step 1. Before turning on, we need to check whether the machine tool is connected to the computer normally, turn on the power and the computer, start the program, and enter the operating system.

Step 2. Select the menu of returning to the origin in the control system to correct the origin coordinates.

Step 3. Load the required processing program, select the open menu, and a standard file operation dialog box will pop up, from which you can select the drive, path and file name where the file to be opened is located. After clicking the open button, the processing program is loaded into the system.

Step 4. Determine the origin of the workpiece, manually move the X and Y axes to the predetermined position on the workpiece, select the menu of setting the current point as the origin of the workpiece, or clear the coordinate value of the current position in the coordinate window. In this way, when executing the processing program, it will start processing with the current position as the starting point.

Buyer's Guide

1. Consult:

We will recommend the most suitable stone CNC machine to you after being informed by your requirements. You should tell us the material you want to carve, the max size of the stone (Length x Width x Thickness).

2. Quotation:

We will offer you with our detail quotation according to the consulted CNC stone router. You will get the most suitable specifications, the best accessories and the affordable price.

3. Process Evaluation:

Both sides carefully evaluate the details (including technical parameters, specifications and business terms) of the order to exclude any misunderstanding.

4. Placing Order:

If you have no doubts, we will send you the PI (Proforma Invoice). Then we will sign a contract with you.

5. Production:

We will arrange the CNC stone cutting machine production as soon as receiving your signed sales contract and deposit. The latest news about production will be updated and informed to you during the production.

6. Quality Control:

The whole production procedure will be under regular inspection and strict quality control. The complete CNC stone cutting machine will be tested to make sure they can work well before out of factory.

7. Delivery:

We will arrange the delivery as the terms in the contract after the confirmation by the CNC stone carving and cutting machine buyer.

8. Custom Clearance:

We will supply all the necessary shipping documents to the buyer and ensure a smooth customs clearance.

9. Support and Service:

We will offer professional technical support and service by Phone, Email, Skype, WhatsApp,